TL;DR: My friends asked me to make custom light up costume headbands for them in the style of Naruto… so I did. I 3D printed channels through which I fed electroluminescent wire to make logos of their favorite DJ’s. While the project is simple in concept, I needed to dust off a bunch of tools I hadn’t utilized in a while to complete it. While I’m not quite finished with these, I’m too excited about how the project is looking NOT to share.

In the anime Naruto, the characters wear headbands to protect their foreheads while they fight. My friends wanted ones that light up for their costumes, and asked if I could help. If you want to skip over a lot of unnecessary detail, just go to the gallery at the bottom where I put the build photos 😛

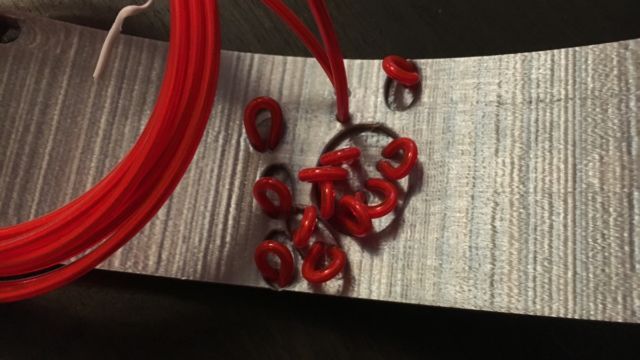

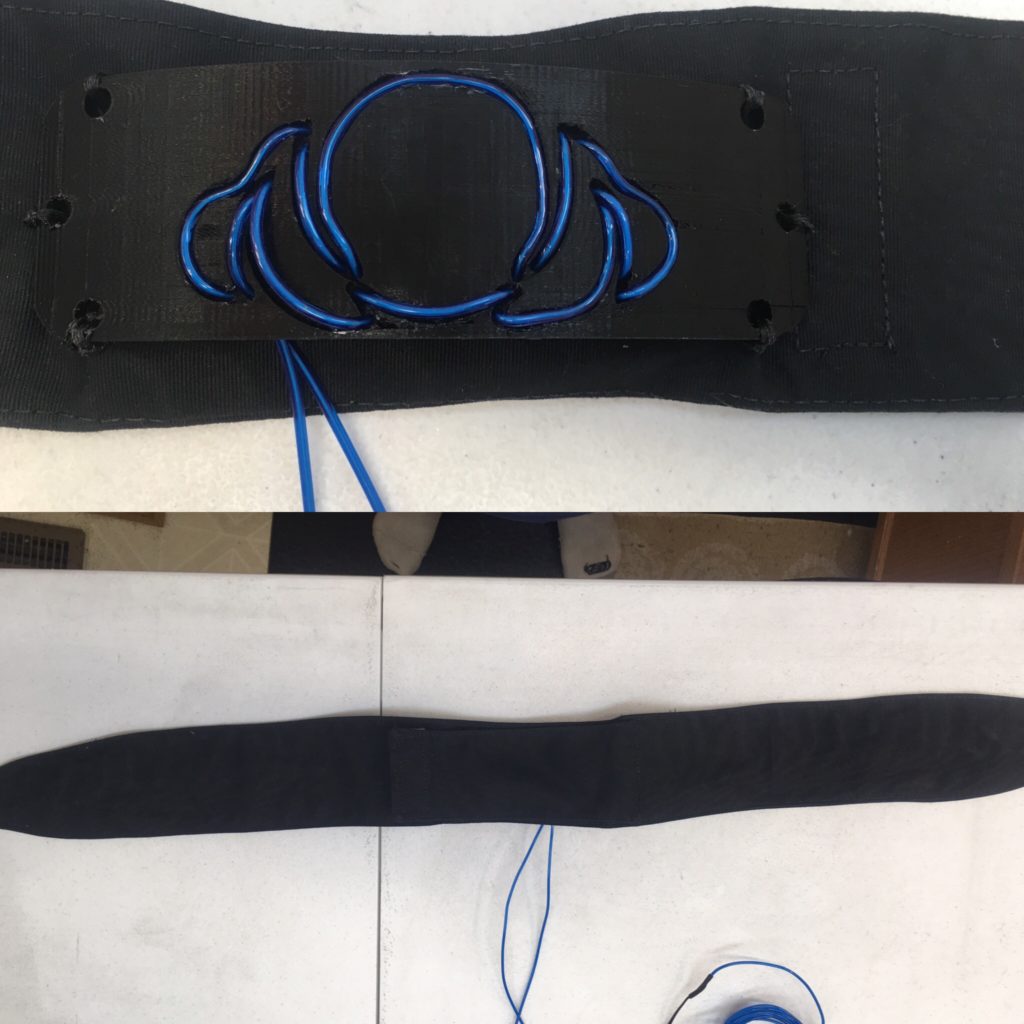

El wire is a fantastic way to add lighting effects to projects since it is very bendable, easy to install, and does not require any programming at all (just add power!). Before this project, I hadn’t played with electroluminescent (el) wire for years, so I was excited to jump back in. The technology has become a lot more common and widely available than I remember—there’re tons of vendors for wire and the requisite DC to AC inverters. Unfortunately, the inverters still make an annoying high pitched buzz whenever they’re on.

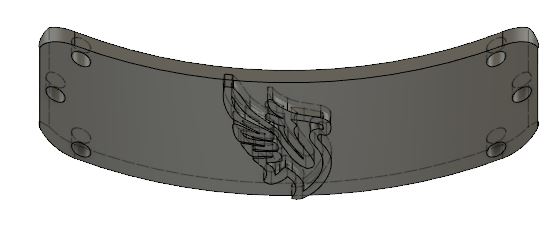

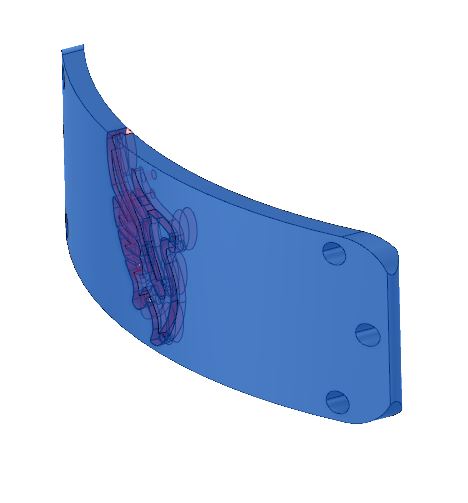

In terms of the mechanical design, the headband was very simple. I created a base in Fusion 360 CAD to reuse in each version with a different logo. The majority of my time has actually been spent optimizing the image preparation pipeline. To go from a 2D-logo to a cut channel, the process I went through was as follows:

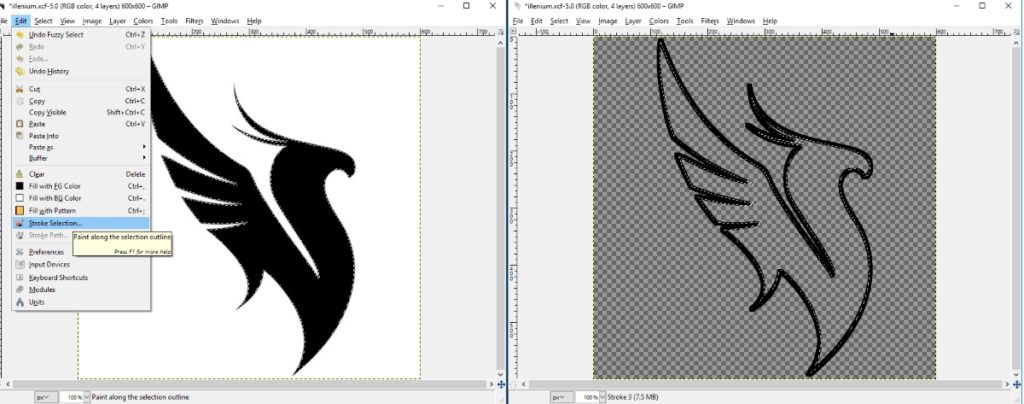

- Prepare an outline image in Gimp (a free Photoshop competitor). The easiest way I found to do this was by using the fuzzy select tool to select the outline of the image I wanted to convert, then using the stroke selection tool.

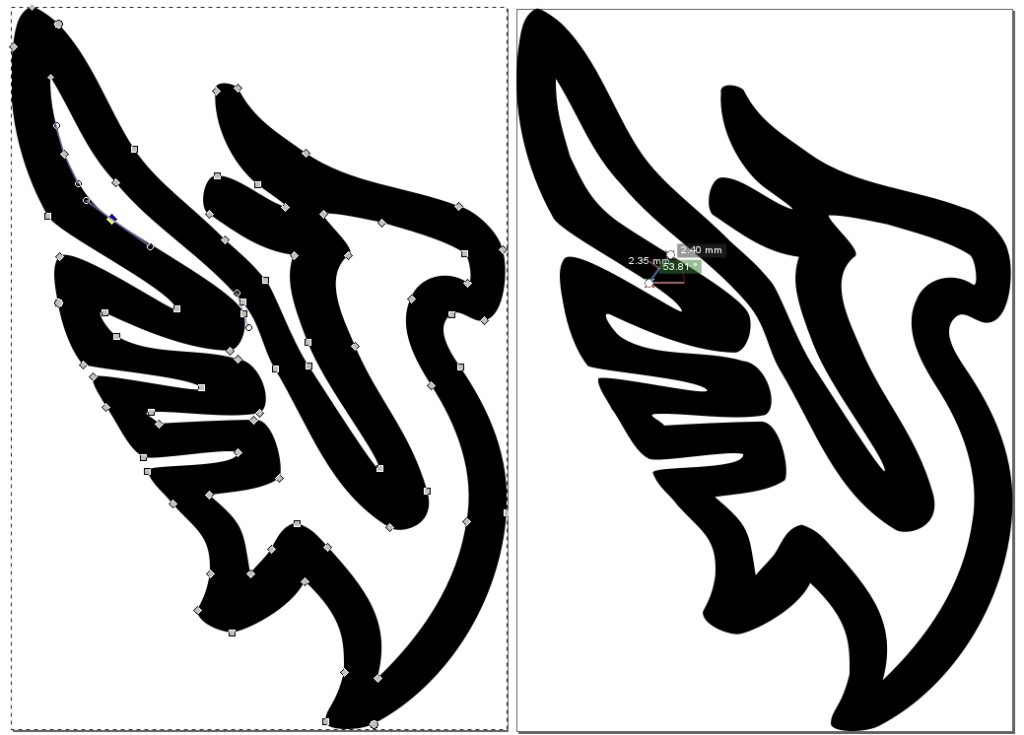

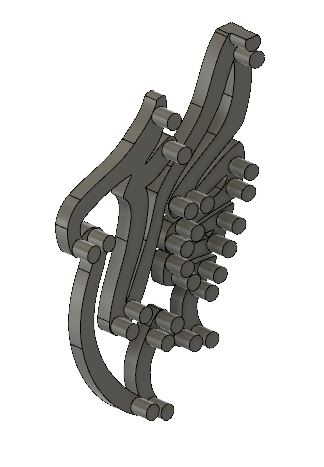

- After saving the image as a bitmap in Gimp, I imported the file in Inkscape (similar to Adobe Illustrator) and stroked the bitmap to a path. I resized the vector image to fit my headband base, and manually edited the nodes until all parts of the path were approximately 2.5mm in width to fit my el wire.

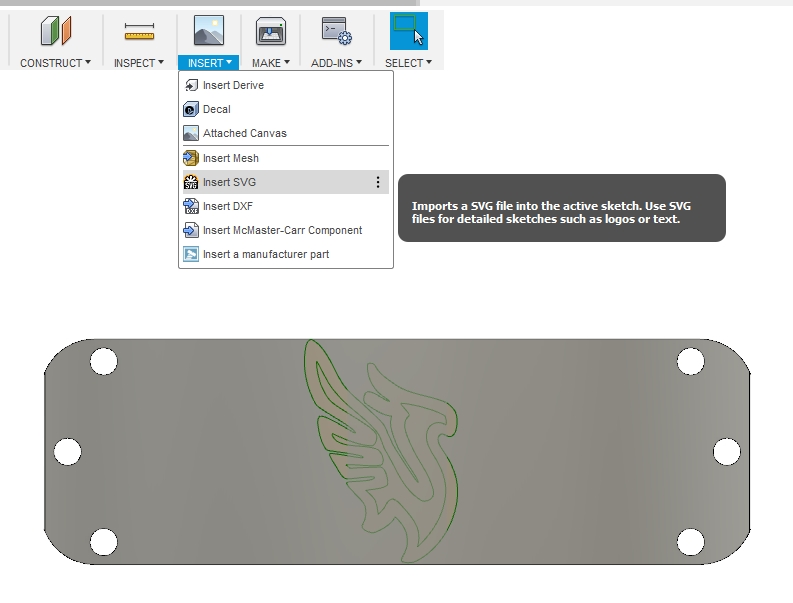

- Initially, I was exporting vector images as 2D CAD-friendly DXF files. However, I made the groundbreaking discovery that Fusion 360 actually lets you directly import and use SVG files. Using the vector files (svg) directly is a lot more computationally friendly and MUCH easier to work with. For example, the dxf version of the Illenium logo had upwards of 670 line elements, whereas the svg file had two curves.

- Within Fusion 360, I directly extruded the imported drawing. Next, I did a few manipulations with the combine and move bodies menu to create a “positive” model of the channel I wanted to CUT from the headband.

- One of the limitations of working with el wire is that there is a minimum bend radius before you can actually break the wire and cause shorts. Unfortunately, since I was making headbands most of the detailed bends weren’t physically possible to make in a single piece. To maintain sharp edges required for the logo designs, I created pass through holes. This allows me to bend the wire in an unsightly loop where it can’t be seen in the final product. Positive models of the pass through holes were created by extruding cylinders from behind the headband up to the channel model.

- Lastly, I created some “channels” on the back of the headbands to accommodate the loops. In an early prototype, I created actual channels out of spline sketches, but that proved to be a lot of work for no reason. Now, I’ve simply created large inset areas that can fit the el wire loops. It’s much less effort to achieve the same result. The positives for this were extruded initially as separate bodies to the channels so I could shift them backward about 0.8mm before joining to the rest of the positive channel model.

- A simple combine, export as STL, and slicing in Cura resulted in a pretty decent print, if I do say so myself ;).

The first prototype I printed was in black PLA before I received this gorgeous silk silver shiny PLA made by Hatchbox on Amazon. I quickly realized that I didn’t have a great way of making the fabric for the bands since I don’t have any sewing skills. I am incredibly lucky to have super talented parents (check out my dad’s website here… he’s much more artistically talented than I am: www.bounsaypipathsouk.com) who are always willing to help. I Facetime called them to explain what I was making and mailed them my first sample. A few days later, I received some photos of my prototype solidly attached to a custom headband they made, and should receive them next week :D.

While there are still a few improvements left for me to make before I deliver my final product, I’m pretty stoked at how well the project has turned out so far, and just couldn’t wait to share.

As promised, here’s a gallery of the build: